Roofing Sheets Corrugated Bendigo: Unveiling a Sustainable and Versatile Solution

Introduction

In the realm of construction and infrastructure, roofing materials play an indispensable role in protecting buildings from the elements. Among these, corrugated roofing sheets have emerged as a versatile and popular choice, particularly in regions with diverse climates. This article delves into the world of “Roofing Sheets Corrugated Bendigo,” exploring its definition, history, global impact, and the various factors shaping its significance. By examining these aspects, we aim to provide valuable insights for professionals, researchers, and anyone interested in sustainable building solutions.

Understanding Roofing Sheets Corrugated Bendigo

Definition and Structure

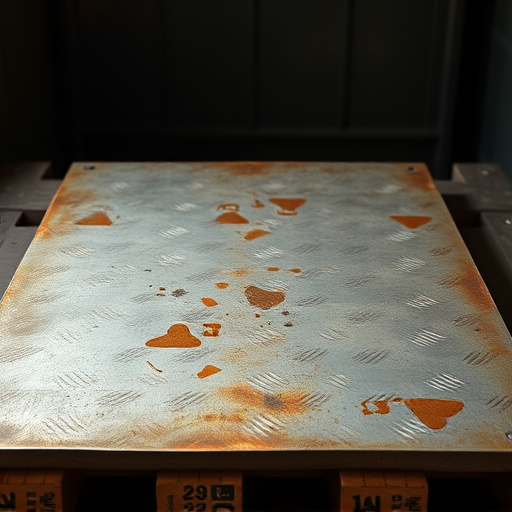

Roofing Sheets Corrugated Bendigo, often simply referred to as corrugated metal roofing, is a type of roofing material characterized by its wavy or corrugated pattern. It consists of steel sheets with indentations or ridges running along their length, creating a unique and robust structure. This design provides several advantages, including improved strength, better weight-to-strength ratio, and enhanced weather resistance.

The core components of these roofing sheets include:

- Steel: The primary material, known for its durability, strength, and corrosion resistance when properly treated.

- Corrugation Pattern: The distinctive wavy design that lends the sheet its unique properties. This pattern can vary in depth and spacing, affecting the sheet’s performance in different weather conditions.

- Coatings: To protect the steel from rust and enhance aesthetics, corrugated sheets often undergo galvanization or are coated with protective substances.

Historical Context

The concept of corrugated metal roofing traces back to the 19th century when inventors sought more affordable and efficient building materials. In the early days, corrugated iron roofs were popular in Europe and Australia due to their ease of installation and lower cost compared to traditional slate or tile roofs. Over time, advancements in steel production and coating techniques improved the durability and longevity of these sheets.

In Bendigo, a city in Victoria, Australia, corrugated roofing gained traction as a practical and cost-effective solution for local buildings. The region’s diverse climate, with hot summers and cold winters, necessitated roofing materials that could withstand extreme conditions. Corrugated sheets, with their superior weather resistance, became a popular choice for residential, commercial, and industrial structures.

Global Impact and Trends

International Influence

The use of corrugated roofing sheets has spread beyond Bendigo and Australia, becoming a global phenomenon. Its influence can be observed across various continents, each adopting and customizing this material to suit local needs:

- Europe: Corrugated metal roofing is widely used in countries like the United Kingdom, Germany, and France. In the UK, for instance, it is popular for agricultural buildings and as a retrofitting option for traditional homes.

- North America: The United States and Canada have embraced corrugated roofing for residential, commercial, and industrial applications. Its durability makes it ideal for areas prone to severe weather conditions.

- Asia: In countries like China, India, and Japan, corrugated metal sheets are extensively used in construction due to their cost-effectiveness and ease of installation.

- Africa: Many African nations have also adopted corrugated roofing, especially in urban areas, where its affordability and speed of installation are highly valued.

Key Global Trends

Several trends shape the future of corrugated roofing sheets globally:

- Sustainability Focus: There is a growing demand for eco-friendly building solutions, leading to increased use of recycled steel and innovative recycling techniques for these sheets.

- Customized Designs: Architects and designers are exploring ways to personalize corrugated roofs, integrating them into modern aesthetics while retaining functionality.

- Smart Technologies Integration: The integration of smart sensors and technology in roofing materials is an emerging trend, enabling real-time monitoring of structural health and weather conditions.

- Off-Grid Applications: Corrugated sheets are finding use in remote areas without access to traditional utility services, thanks to their versatility and off-grid compatibility.

Economic Considerations

Market Dynamics

The global corrugated roofing sheets market is characterized by a competitive landscape with several prominent manufacturers and suppliers. The demand for these sheets is influenced by factors such as:

- Construction Industry Growth: Rising global construction spending drives the need for roofing materials, including corrugated sheets.

- Climate Change and Extreme Weather: As climate patterns become more unpredictable, there is an increasing demand for durable roofing solutions, propelling the market growth.

- Infrastructure Development: Developing countries’ focus on infrastructure improvement projects contributes significantly to the market’s expansion.

Investment Patterns

Investment in corrugated roofing sheet manufacturing and distribution follows regional trends:

- Asia-Pacific Dominance: This region accounts for a substantial share of the global market due to rapid construction activities, particularly in China and India.

- North America and Europe Growth: The North American and European markets exhibit steady growth, driven by infrastructure upgrades and retrofitting projects.

- Emerging Markets Opportunities: Countries in Southeast Asia, Latin America, and Africa present promising opportunities for market expansion due to increasing urbanization and construction activities.

Economic Impact

The economic impact of corrugated roofing sheets is multifaceted:

- Cost Efficiency: These sheets offer a cost-effective solution for roofing, making them attractive to developers, contractors, and homeowners alike.

- Job Creation: The manufacturing, installation, and maintenance of corrugated roofs contribute to job growth in the construction sector.

- Material Diversification: The use of recycled steel and innovative production methods promotes economic sustainability and reduces reliance on traditional materials.

Technological Advancements

Innovation in Corrugated Roofing

Technological advancements have played a pivotal role in improving corrugated roofing sheets:

- Galvanization Techniques: Advances in galvanization processes have enhanced the corrosion resistance of these sheets, increasing their lifespan.

- Coating Technologies: Modern coating techniques allow for better adhesion and longer-lasting finishes, protecting the steel from environmental factors.

- Computerized Design and Cutting: Precision computer-controlled cutting ensures accurate sheet fabrication, reducing waste and improving installation efficiency.

Future Potential

The future holds immense potential for technological innovation in corrugated roofing:

- Smart Roofing Systems: Integrating IoT (Internet of Things) technology can enable real-time monitoring of roof conditions, predictive maintenance, and energy-efficient ventilation systems.

- 3D Printing and Customization: 3D printing technologies may revolutionize custom designs, allowing for intricate patterns and unique architectural expressions.

- Solar Integration: Corrugated roofing sheets with integrated solar panels could become a popular choice for sustainable energy generation in buildings.

Policy and Regulation

Governance and Standards

The use of corrugated roofing sheets is subject to various policies and regulations that ensure quality, safety, and environmental sustainability:

- Building Codes: Local building codes dictate the acceptable types of roofing materials, including specifications for corrugated sheets, load-bearing capacity, and installation standards.

- Environmental Regulations: Many countries have strict guidelines regarding the use of recycled materials and the disposal of manufacturing waste to minimize environmental impact.

- Safety Standards: There are safety regulations in place to protect workers during manufacturing and installation, ensuring proper handling of steel sheets and equipment.

Influencing Factors

Policies and regulations significantly influence the development and adoption of corrugated roofing:

- Encouraging Sustainable Practices: Incentives and subsidies for using recycled materials and energy-efficient designs can drive innovation and market acceptance.

- Standardization and Certification: Implementing standardized testing and certification processes ensure product quality and performance, fostering consumer confidence.

- Local Adaptation: Regulations must adapt to regional climates and construction practices to ensure the suitability of corrugated roofs across diverse areas.

Challenges and Criticisms

Overcoming Barriers

Despite its numerous advantages, corrugated roofing sheets face certain challenges and criticisms:

- Initial Cost: While long-term savings are significant, the initial investment for installation can be a barrier, especially for smaller projects or individuals on tight budgets.

- Weight and Load Considerations: Despite being strong, these sheets may require additional structural support in some cases, particularly for older buildings or unique architectural designs.

- Aesthetic Appeal: Traditional corrugated sheets are often associated with industrial or rural settings, which may not align with modern urban aesthetics. However, custom designs and color options can address this concern.

Proposed Solutions

Addressing these issues requires a multi-faceted approach:

- Financing Options: Offering leasing or financing schemes for roofing installations can make the initial cost more manageable for homeowners and businesses.

- Structural Assessments: Conducting thorough structural assessments before installation ensures that buildings can support the weight of corrugated roofing, mitigating potential risks.

- Aesthetic Customization: Encouraging architectural designers to explore creative ways to incorporate corrugated roofs into modern building designs can enhance their visual appeal.

Case Studies

Success Stories

The following case studies highlight successful applications and outcomes:

- Residential Renovation in Australia: In a suburban Melbourne home, corrugated roofing was used as part of a renovation project to create a unique, industrial-chic interior. The sheets were cut into custom shapes and installed with a reflective coating, reducing energy consumption and providing an eye-catching design element.

- Commercial Building in the US: A tech startup in Silicon Valley opted for corrugated metal roofing for its new headquarters. This choice not only reduced construction costs but also provided the flexibility required to install advanced solar panels, contributing to their sustainability goals.

- Rural Community Project in Africa: In a remote African village, a community center was constructed using locally sourced corrugated sheets. The project aimed to provide a durable and cost-effective roofing solution for a much-needed community space, fostering local pride and self-reliance.

Lessons Learned

These case studies offer valuable insights:

- Customization and design play a crucial role in making corrugated roofing aesthetically pleasing and aligning with specific project goals.

- Local sourcing of materials can be cost-effective and environmentally friendly, as demonstrated by the African community center project.

- Corrugated sheets’ versatility allows for integration of advanced technologies like solar panels, enhancing sustainability and functionality.

Future Prospects

Growth Areas

The future holds promising opportunities for corrugated roofing sheets:

- Sustainable Construction: With a growing focus on green buildings, corrugated sheets made from recycled steel or incorporating eco-friendly coatings will be in high demand.

- Off-Grid Communities: Remote areas without access to traditional utility services will continue to benefit from the affordability and versatility of these roofs.

- Smart Cities: The integration of smart technologies in roofing systems could contribute to the development of ‘smart cities,’ enabling efficient energy management and real-time structural monitoring.

Emerging Trends

Several emerging trends shape the future:

- 3D Printing for Customization: 3D printing technology will enable on-demand customization, allowing for unique designs and rapid prototyping.

- Integration with Renewable Energy: Corrugated roofs with integrated solar panels or wind turbines could become a common sight, promoting sustainable energy generation.

- Modular Roofing Systems: Modular designs offer faster installation and easier maintenance, appealing to developers and homeowners seeking efficient solutions.

Strategic Considerations

To capitalize on these prospects, industry players should:

- Invest in research and development for eco-friendly materials and innovative technologies.

- Explore partnerships with smart city initiatives to integrate roofing systems into urban infrastructure.

- Adapt manufacturing processes to accommodate custom designs while maintaining quality standards.

Conclusion

“Roofing Sheets Corrugated Bendigo” has evolved from a simple roofing material to a versatile, sustainable solution with global implications. Its historical roots in Bendigo have contributed to its widespread adoption and continuous innovation. As the world navigates the challenges of climate change and rapid urbanization, corrugated metal roofing stands as a testament to human ingenuity, offering practical and efficient solutions.

The future prospects for this technology are bright, with potential advancements in sustainability, customization, and smart integration. By addressing current challenges and embracing emerging trends, the industry can unlock new heights of innovation, ensuring that corrugated roofing sheets remain a reliable and adaptable choice for generations to come.

FAQ Section

Q: Are corrugated roofing sheets suitable for all types of buildings?

A: Corrugated sheets are highly versatile and suitable for various building types, from residential homes to commercial structures and industrial facilities. However, proper structural assessment is essential to ensure compatibility with existing buildings, especially older structures.

Q: How do I choose the right type of corrugated roofing for my project?

A: Consider factors like climate conditions, budget, aesthetic preferences, and building structure. Modern options include various profiles, colors, and coatings, allowing you to match your roof with your design vision. Consult professionals or manufacturers to determine the best choice based on your specific needs.

Q: Can corrugated roofing sheets be easily installed?

A: With proper planning and preparation, corrugated sheets can be relatively easy to install. Many manufacturers offer detailed installation guides and videos. However, for complex designs or large projects, professional installers are recommended to ensure quality and safety.

Q: Are there any environmental concerns associated with corrugated roofing?

A: While traditional steel production has environmental impacts, modern manufacturing techniques and recycled materials minimize these effects. Additionally, the longevity of corrugated roofs reduces the need for frequent replacements, contributing to sustainability.

Q: How do I maintain corrugated metal roofing?

A: Regular cleaning and inspection are essential for maintaining the integrity of these roofs. Remove debris, treat rust spots promptly, and consider periodic coatings or sealing to protect against corrosion. For detailed maintenance guidelines, refer to manufacturer recommendations.

The Steeline Bendigo Centre offers high-quality corrugated roofing sheets for residential and commercial projects, featuring diverse styles, excellent durability, and easy installation. Their products cater to local climate conditions and archit…….

Continue Reading

Steeline Bendigo offers durable and versatile corrugated iron roofing sheets suitable for various projects across the region. These sheets, known for their corrosion resistance, lightweight design, and adaptability, cater to both traditional and…….

Continue Reading

Steeline Roofing Centre Bendigo is your local partner for superior roofing solutions, offering top-tier corrugated roofing sheets designed to withstand harsh weather conditions and enhance property aesthetics. With a deep understanding of Bendig…….

Continue Reading

Steeline Roofing Centre Bendigo is a trusted provider of high-quality corrugated roofing solutions for both residential and commercial projects. Their innovative sheets feature a sturdy wavy pattern, enhancing strength while maintaining minimal…….

Continue Reading

Steeline Roofing Centre in Bendigo is a leading provider of high-quality corrugated roofing sheets, offering superior durability, corrosion resistance, and insulation for residential and commercial properties. Their extensive range caters to div…….

Continue Reading

Steeline Roofing Centre Bendigo is a leading provider of quality corrugated metal roofing solutions for residential, commercial, and industrial sectors in Australia. With robust, affordable, and weather-resistant options like traditional galvani…….

Continue Reading

Steeline Roofing Centre Bendigo is a leading supplier of high-quality, durable corrugated roofing sheets suitable for various climates and applications. They offer bulk purchases for cost savings, with options including metal, plastic, and fiber…….

Continue Reading

Steeline Bendigo offers a wide range of durable and cost-effective corrugated roof sheets suitable for extreme climates, like those found in Bendigo. Made from aluminium or zinc, these sheets provide structural integrity and protection against h…….

Continue Reading

Steelee Roofing Centre Bendigo is your local, trusted provider of high-quality Steeline corrugated roofing sheets designed for Australia's conditions. Offering top-notch products and exceptional service, they have a comprehensive range suit…….

Continue Reading

Corrugated roof sheets from Steeline Bendigo offer a versatile, durable, and energy-efficient solution for both residential and commercial projects in warmer regions like Bendigo. With a wide range of colored options, homeowners and builders can…….

Continue Reading

Steeleen Roofing Centre Bendigo provides top-quality roofing sheets for sheds and homes, catering to diverse customer needs. They offer expert advice, a wide range of products, including metal and durable alternatives, and robust installation se…….

Continue Reading

Steeleline Roofing Centre Bendigo is a local, trusted provider of roofing solutions, offering a wide range of services and high-quality corrugated roofing sheets. Located at 6 Harrien Ct, Epsom VIC 3551, Australia, they can be reached at +61 3 5…….

Continue Reading

Steeline Roofing Centre Bendigo, located at 6 Harrien Ct, Epsom VIC 3551, Australia, offers trusted commercial roofing solutions, specializing in high-quality corrugated sheets. Their expert team ensures projects meet excellence standards. These…….

Continue Reading

Steeline Bendigo offers high-quality, durable corrugated roofing sheets suitable for various architectural styles and weather conditions in Bendigo. Their products are lightweight, easy to install, cost-effective, and come with warranties. Measu…….

Continue Reading

Steeline Roofing Centre Bendigo is a trusted provider of high-quality corrugated roof sheets for both residential and commercial projects in Epsom, VIC 3551, Australia. Located at 6 Harrien Ct, they offer expert advice, exceptional service, and…….

Continue Reading

Corrugated roofing sheets from Steeline Roofing Centre Bendigo offer superior durability and versatility for both residential and commercial projects, with various materials and styles available. Their unique ripple pattern enhances structural s…….

Continue Reading

Steeline Bendigo provides high-quality, durable corrugated roofing sheets for homes and businesses, offering exceptional weather, impact, and fire protection. With various sizes and styles available, their precision-manufactured products cater t…….

Continue Reading

Corrugated roofing sheets in Bendigo from Steeline offer superior strength, durability, and adaptability, enhancing structural integrity and energy efficiency. Their lightweight yet robust construction enables quicker, cost-effective installatio…….

Continue Reading

Steeline Roofing Centre Bendigo is a leading provider of metal roofing solutions, offering high-quality corrugated metal sheets and expert services tailored for both residential and commercial needs. Located at 6 Harrien Ct, Epsom VIC 3551, Aust…….

Continue Reading